The pace of rail transit construction has accelerated, and the increase in mileage of railway operations has led to the expansion of demand for rail transit cables, and the demand for wires and cables has also increased.

Due to the particularity of rail transit construction, higher requirements are placed on the technical level of safety and environmental protection of wire and cable products.

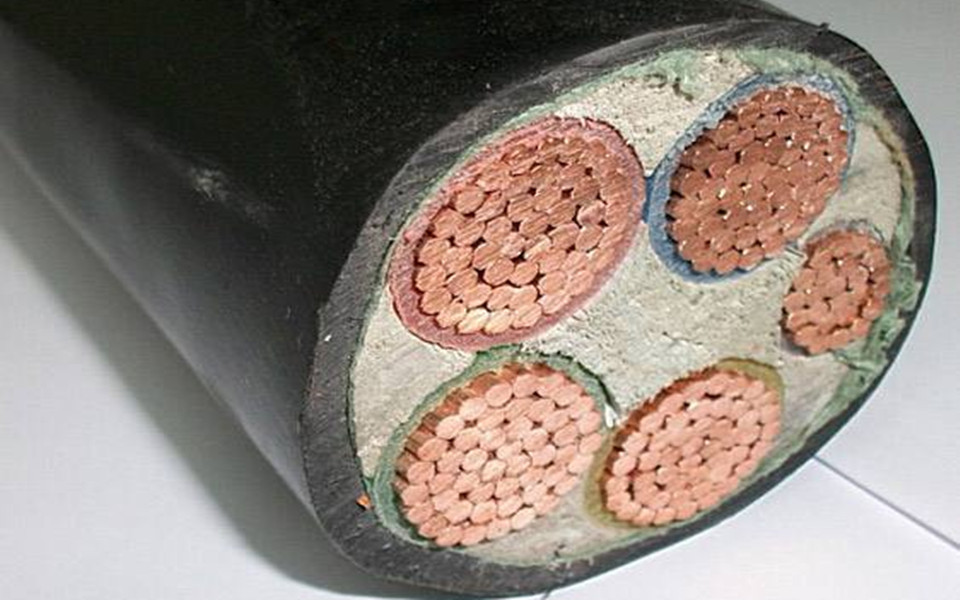

In addition to excellent electrical and insulating properties, wire and cable must have good flame-retardant properties, water-blocking performance, and rodent resistance, so the product has a new update in material selection and routing compared to traditional power cables.

The following is an introduction to the problems and solutions that are easy to occur in the production process.

The main problems in the manufacturing process of rail power cables are insulation eccentricity, comprehensive sheath irregularity, and high spark breakdown rate; halogen-free low-smoke flame-retardant polyolefin materials are not smooth and have pores.

After repeated analysis and experimentation, the main reasons for these problems are as follows:

Since the thickness of the insulation is relatively thick, the contact surface between the insulation and the conductor is small.

Therefore, under the condition of high temperature and high pressure in the cross-linked tube, the plastic is in a viscous flow state, and there is a certain degree of sag so the eccentricity is unacceptable.

The main reasons for this problem are:

(1) The longitudinally wrapped aluminum plastic belt is unevenly stressed during molding, resulting in wrinkles of the longitudinal package.

(2) When the aluminum-plastic composite tape is longitudinally wrapped, the interface is not bonded to cause lifting.

(3) Aluminum plastic belt flange.

(4) Foaming, perforation, etc. of halogen-free low-smoke flame-retardant polyolefin materials.

The main reasons for this problem are:

(1) Improper storage of raw materials, resulting in dampness.

(2) Due to the low processing temperature of the material, excessive extrusion temperature may cause foaming of the material.

(3) Due to the high flame retardancy, a large amount of filler is added to the raw material, which tends to cause uneven appearance, cracks, and the like during extrusion.