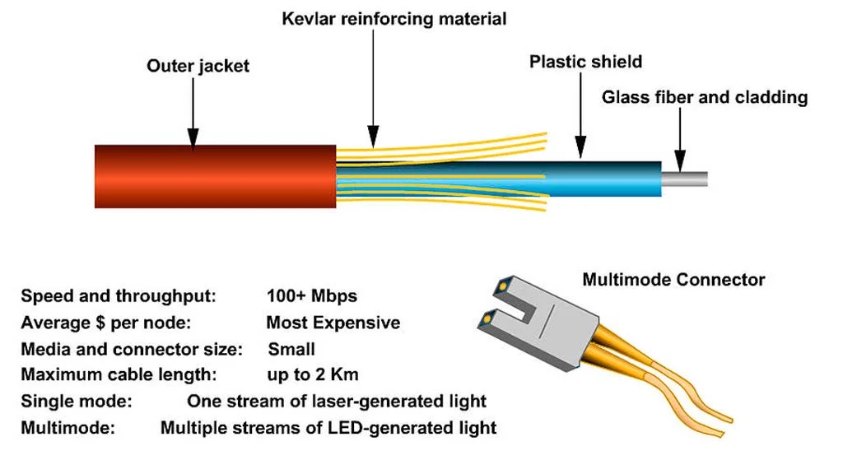

Fiber optic cable or optical fiber is a flexible, transparent fiber. It is made of glass (silica) or plastic stretched to a diameter slightly thicker than the diameter of a human hair.

Optical fibers are most often used as a means of transmitting signals between the two ends of an optical fiber.

Multi core fiber optic cable is the presence of multiple cores in a common cladding area. Due to the proximity of the cores to each other, two functions are possible.

Let's start with the structure of a common single-core fiber.

The cross-section of a normal single-core fiber is composed of a core, a cladding, and a coating layer from the inside to the outside, cladding and coating layer.

The core and cladding are made of glass with different refractive indices, and the cladding is an elastic coating that is cured with UV light to protect the fiber while it is being pulled from the preform.

The diameter of ordinary hair is about 60um to 90um, and although the cladding diameter of a single-core fiber power cable is similar to that of ordinary hair, it is still too large relative to the diameter of the mode field.

So there is the production method of putting more fiber cores in the cladding, for example, 7 cores in the cladding.

One is a structure with large core spacing, i.e., no optical coupling.

This type of fiber is due to the ability to increase the integrated density per unit area of the transmission line.

In multicore fiber optic communication, it can be made into a ribbon cable with multiple cores, and in the non-communication field, as a fiber optic transmission bundle, there are made into thousands of cores.

The second is to make the distance between the cores close to each other, which can produce a light-wave coupling effect.

This principle is being used to develop a dual-core sensitive or optical circuit device.

Standard: IEC 60793; ITU G651.1; ITU G652-G657

Type: single mode/multiple modes

Multi-Core: 2-144 fibers

Loose Tube: FRP

Central strength member: FRP

Filling: Jelly compound

Wrapping: water-blocking tape

Sheath: PE

A Fiber Optic Cable or multicore fiber cable is a flexible, transparent fiber made by drawing glass (silica) or plastic to a diameter slightly thicker than that of a human hair.

The flexible optical cable is used most often as a means to transmit light between the two ends of the fiber and finds wide usage in fiber-optic communications, where they permit transmission over longer distances and at higher bandwidths

(data rates) than wire cables.

Fibers are used instead of metal wires because signals travel along them with less loss; in addition, fibers are immune to electromagnetic interference, a problem from which metal wires suffer excessively.

Fibers are also used for illumination and imaging and are often wrapped in bundles so that they may be used to carry light into, or images out of confined spaces, as in the case of a fiberscope.

Specially designed fibers are also used for a variety of other applications, some of them being fiber optic sensors and fiber lasers.

ZMS Power Cable Manufacturer provides you with the best fiber optic cable solution.

Powered Fiber optic cords use Gigabit Ethernet, active device termination, telecommunication networks, video, multimedia, premise installations, local area networks, FTTH FTTX applications, and CATV.

If you don’t know how to choose the products you need or don’t find the cable type and size you need on this page, don’t worry. Contact us and send us your requirements, and we can help you choose the right cable.

You can provide us with the following information: cable voltage, conductor material, insulation and sheath material, shield type, armor type, etc. or you can provide us with cable installation environment, application requirements, etc.

We will serve you wholeheartedly. ZMSCable Supplier has a number of quality certifications: ISO 9000, ISO 9001, ISO14000, ISO14001, ISO18000, CE, IEC, BS, NFC, ASTM, DIN, etc.

And we will also provide you with a selection of cable accessories such as cable glands, fiber connection sac, and connectors. By choosing ZMS cables you will have a complete cable solution.

ADSS fiber meaning: All-Dielectric Self-Supporting Cable

OPGW Fiber Optic (Optical Power Ground Wire)

OPGW meaning: Optical Ground Wire

| fiber160/count | 2-36 | 38-60 | 62-72 | 74-96 | 98-120 | 122-144 | 146-216 |

| nominal diameter (mm) | 12.8 | 14 | 14.7 | 16.1 | 17.6160 | 19.1 | 19.3160 |

| nominal weight (kg/km) | 187 | 208 | 220 | 260 | 293 | 356 | 375160 |

| permitted tensile160/LT/ST(N) | 600/1500 (1000/3000) | 1000/3000 | 1000/3000 | 1000/3000 | 160;1000/3000 | 1000/3000 | 160;1000/3000 |

| permitted crush LC/SC(N) | 300/1000 (1000/3000) | 1000/3000 | 1000/3000 | 1000/3000 | 160;1000/3000 | 1000/3000 | 160;1000/3000 |

| bend radius static state/ dynamic state (mm) | 12.5D/25D | 12.5D/25D | 12.5D/25D | 12.5D/25D | 160;12.5D/25D | 12.5D/25D | 160;12.5D/25D |

There is no news related to this product.

ZMS Cable have a wide product scope, includes: Power cables up to 500kV, AAC, AAAC, ACSR conductors, ABC Cable,electric wires, instrument cable, telecommunications cable, Stay wires. With advanced manufacture technology, rich human resource and effective management system, we guarantee all products are manufactured strictly in accordance with GB, IEC, BS, NFC, ASTM, DIN standards,etc. Beyond quality control, ZMS have been trying its best to offer much higher standard of services rather than expected.

You can contact us in the following ways:

email to sales@zmscable.com OR click Inquiry