Electricity is the lifeblood of modern civilization, and the cables that carry it are crucial for a wide range of applications, from powering household appliances to transmitting electricity across vast distances.

Two primary categories of these cables are high voltage (HV) cables and low voltage (LV) cables.

Despite their shared purpose of conducting electricity, they are markedly different in terms of structure, materials, applications, and safety considerations.

This essay ZMS Cable explores the distinctions between high voltage and low voltage cables, providing a comprehensive overview of their structures, categorization, and applications.

High Voltage Cables

High voltage cables are designed to carry electrical currents at voltages above 35 kV (kilovolts). These cables are used in power transmission and distribution networks.

The structure of a high voltage cable is complex, owing to the need for enhanced insulation and mechanical protection to handle high electrical stresses.

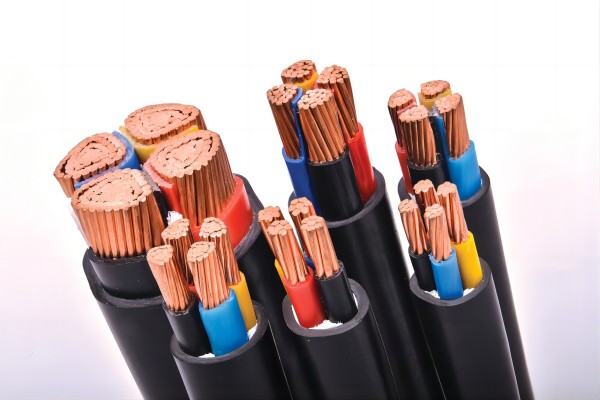

Conductor: The core of a high voltage cable is usually made of copper or aluminum, chosen for their excellent electrical conductivity. The conductor may be stranded or solid, with stranded conductors providing greater flexibility.

Insulation: The insulation is a critical component that prevents electrical leakage and ensures the system's safety. Common insulating materials include cross-linked polyethylene (XLPE), ethylene propylene rubber (EPR), and paper-insulated lead-covered (PILC) compounds. XLPE is particularly favored for its high thermal rating and longevity.

Semiconducting Layers: High voltage cables often include semiconducting layers around the conductor and the insulation. These layers, made of materials like carbon black, smooth the electric field and reduce electrical stress on the insulation.

Metallic Shield: A metallic shield, often made of copper tape or wire, surrounds the insulated conductor. This shield provides a path for fault currents and protects the insulation from mechanical damage and electromagnetic interference.

Outer Sheath: The outer sheath protects the cable from environmental factors such as moisture, chemicals, and physical damage. Materials like polyethylene (PE) and polyvinyl chloride (PVC) are commonly used for the sheath.

Low Voltage Cables

Low voltage cables are designed for voltages up to 1 kV. They are ubiquitous in residential, commercial, and industrial applications with relatively low required voltage. The structure of low voltage cables is simpler compared to high voltage cables.

Conductor: Similar to high voltage cables, low voltage cables use copper or aluminum as the conductor material. The conductors are usually stranded to provide flexibility.

Insulation: The insulation for low voltage cables is generally made from PVC, rubber, or XLPE. PVC is the most common due to its good insulating properties, flexibility, and cost-effectiveness.

Sheath: The outer sheath, often made of PVC, rubber, or other plastics, protects the cable from mechanical damage and environmental factors.

High Voltage Cables

High voltage cables are categorized based on their application and construction:

Transmission Cables: These are used to transmit electricity over long distances, from power plants to substations. They are typically overhead lines but can also be underground or submarine cables for specific applications.

Distribution Cables: These cables carry electricity from substations to end-users, such as homes and businesses. They are designed to handle lower voltages than transmission cables.

Submarine Cables: Used for underwater applications, submarine high voltage cables connect offshore installations, such as wind farms, to the mainland power grid. They are designed to withstand harsh underwater conditions.

Low Voltage Cables

Low voltage cables are categorized primarily by their specific use cases:

Building Wiring: These cables are used for internal wiring in residential, commercial, and industrial buildings. Examples include twin and earth cables, armored cables, and flexible cables for appliances.

Control Cables: Used in control systems, these cables transmit signals rather than power. They are often shielded to protect against electromagnetic interference.

Instrumentation Cables: These cables are used to carry low voltage signals from sensors and instruments to control systems. They are designed for accuracy and reliability.

High Voltage Cables

Power Transmission: High voltage cables are essential for transmitting electricity over long distances with minimal losses. They connect power generation sources, such as hydroelectric, nuclear, and thermal power plants, to substations near consumption areas.

Renewable Energy: With the rise of renewable energy sources, high voltage cables are increasingly used to connect wind farms, solar farms, and other renewable energy installations to the grid. Submarine cables, in particular, play a critical role in offshore wind farms.

Industrial Applications: High voltage cables are used in industries that require large amounts of electricity, such as steel manufacturing, mining, and chemical plants. They ensure a stable and reliable power supply to heavy machinery and equipment.

Low Voltage Cables

Residential Wiring: Low voltage cables are ubiquitous in residential settings, providing power to lighting, outlets, and household appliances. They are designed for safety, flexibility, and ease of installation.

Commercial and Industrial Buildings: In commercial and industrial settings, low voltage cables are used for internal wiring, providing power to equipment, lighting systems, and other electrical devices. Armored cables are often used in industrial environments for added protection.

Control Systems: Automation systems use low voltage control cables to connect control panels with machinery, sensors, and actuators. They ensure the smooth operation of automated processes.

Telecommunications: Low voltage cables are also used in telecommunications, providing power to communication devices and networks. They are designed to minimize signal loss and interference.

High Voltage Cables

Due to the high voltages involved, high voltage cables pose significant safety risks. Proper insulation, grounding, and protective measures are crucial to prevent accidents.

Insulation Integrity: Ensuring the integrity of the insulation is critical to prevent electrical leaks and short circuits. Regular inspections and maintenance are necessary to detect and address potential issues.

Grounding: Proper grounding of high voltage cables is essential to provide a path for fault currents, protecting both the cable and connected equipment from damage.

Protective Gear: Personnel working with high voltage cables must use specialized protective gear, including insulating gloves, boots, and tools for high voltages.

Low Voltage Cables

While low voltage cables pose fewer risks than high voltage cables, safety remains a key concern. Proper installation and adherence to electrical codes are essential to ensure safe operation.

Overcurrent Protection: Low voltage circuits must be equipped with appropriate overcurrent protection devices, such as fuses or circuit breakers, to prevent overheating and fires.

Proper Installation: Cables must be installed according to manufacturer guidelines and local electrical codes to prevent overloading, short circuits, and physical damage.

Maintenance: Regular maintenance and inspections help identify potential problems, such as wear and tear or damage to the insulation, ensuring continued safe operation.

The field of electrical cables is continually evolving, with advancements aimed at improving efficiency, safety, and performance.

High Voltage Cables

Superconducting Cables: Research into superconducting materials has the potential to revolutionize high-voltage cable technology. These materials can conduct electricity with zero resistance, significantly reducing energy losses.

Advanced Insulation Materials: Developing new insulating materials, such as nanocomposites, enhances high voltage cables' durability and thermal performance.

Smart Monitoring Systems: The integration of smart monitoring systems allows for real-time monitoring of cable conditions, such as temperature, pressure, and electrical load, helping to prevent failures and optimize performance.

Low Voltage Cables

Flexible Cables: Advances in materials science have led to the development of more flexible cables, which are easier to install and can withstand greater mechanical stresses.

Fire-Resistant Cables: New materials and designs have improved the fire resistance of low voltage cables, enhancing safety in residential and commercial buildings.

Sustainable Materials: There is a growing focus on using sustainable and recyclable materials in cable manufacturing, reducing the environmental impact of cable production and disposal.

High voltage and low voltage cables are fundamental components of modern electrical systems, each serving distinct but equally important roles. High voltage cables are essential for transmitting and distributing electricity over long distances and in industrial settings, where their complex structures ensure reliability and safety under high electrical stresses.

On the other hand, low voltage cables are integral to residential, commercial, and industrial applications, providing power and control in a wide range of settings.

Understanding the differences in their structures, applications, and safety considerations is crucial for the effective and safe design, installation, and maintenance of electrical systems.

As technology advances, both high- and low-voltage cables will evolve, becoming even more efficient, safe, and environmentally friendly, further supporting the growth and development of our electrified world.