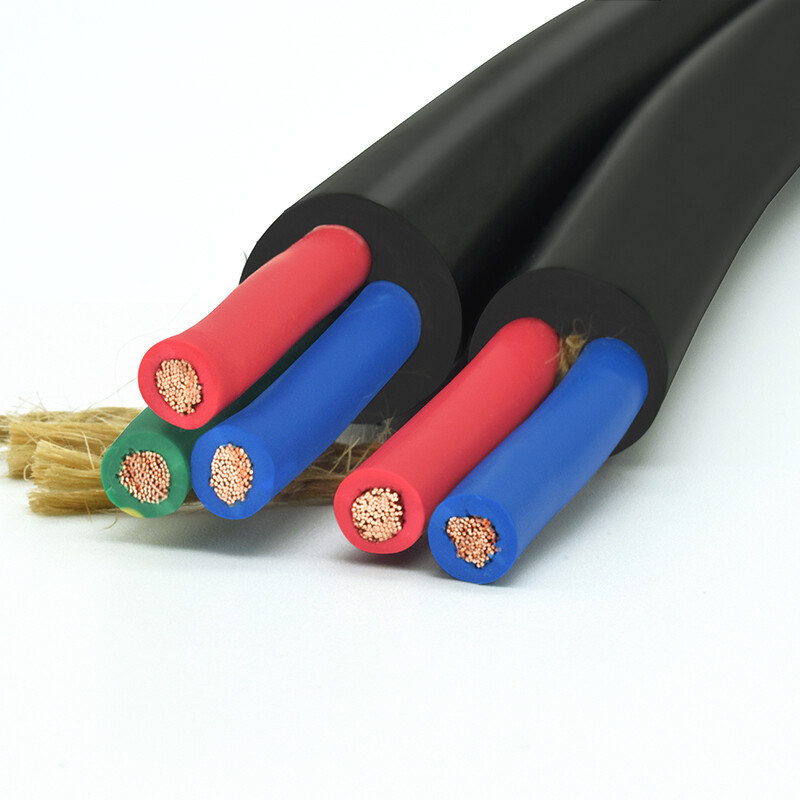

Rubber cable is a fine multi-strand of copper wire conductor, wrapped in rubber insulation and rubber sheath, a kind of soft that can be mobile to a variety of cables. General rubber cable, electric welding machine cable, submersible motor cable, radio equipment, cable, and cable, etc.

In the production process of rubber cables, all sorts of quality problems, the following wallets' hardware mechanical and electrical network will do a preliminary summary and analysis.

The first is the appearance of the problem, the problem is mainly reflected in the following aspects:

Smooth surface

the surface of clinker particles (early vulcanized rubber particles) or impurities

wire and cable surface scratch, scratch

surface subsidence; surface twist pattern

To make a simple analysis of the above problems:

1. The die sets the line is too long or too short, the die is not smooth and the aperture is too large; the nose, die or the body temperature is low; the rubber plastic small and so are likely to lead to rubber cable surface is not smooth.

2. The supply of the rubber is not clean, containing impurities; rubber scorch time is too short. Squeeze rubber body, the nose or mouth mold temperature is too high; head rubber flow is not smooth, rubber material stranded dead; the screw is not smooth, viscose and so on may lead to the emergence of clinker particles (early vulcanized rubber particles) or impurities capture cable surface.

3. The die set is not smooth, without chamfering; impurities or glue particles blocking die; in the vulcanizing tube drag pipe abrasion; vulcanization pipe outlet sealing rubber washer smaller pore size were may lead to cable, rubber surface scratches and abrasions.

4. A die sleeve aperture is too large; conductive wire core outer layer strands, the single gap is too large, the outer diameter of the cable core is not uniform; rubber material plastic, viscosity is poor; rubber material impurities; to die from the small, small pressure and so on were may lead rubber cable surface subsidence.

5. A die sleeve aperture is too small; rubber material extrusion problems, the wire core slot fills dissatisfaction; conductive wire core or cable jumper; on short distance modulus were may lead to twisting grains on the surface of the rubber cable.