The installation unit will use the cable terminal cover, plastic tape, wiring nose, galvanized screw, cable clamp and other materials to fill the engineering materials / structural parts / equipment review.

Supervision engineer to be signed after the check.

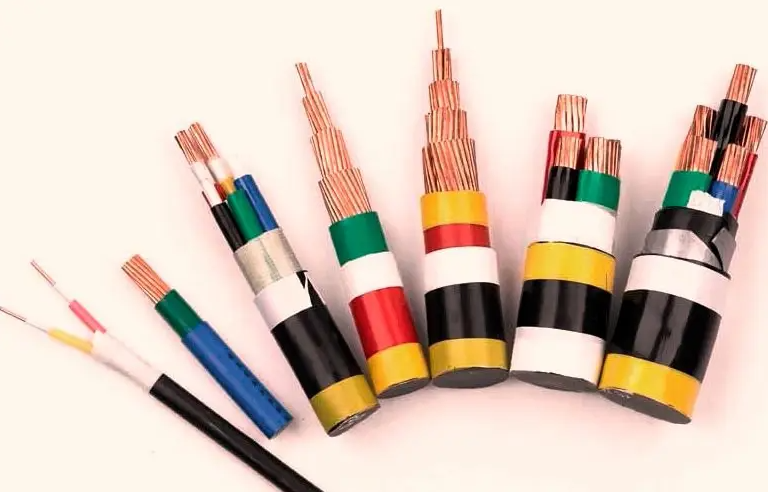

(1) use 1000V shake the table to shake the cable, the insulation resistance should be more than 10MΩ.

(2) the use of the cable itself, the steel bandwidth of the 1/2 to do the clip, the use of plastic mouth to catch the card, you must play two, to prevent the release of steel. Micro-signal skills training is worth your attention.

(3) the use of soldering in the cable on the cable grounding wire, must be very strong.

(4) cable terminal must be fixed on the cable head firmly, phase sequence should be correct.

(5) line nose and cable core cross-section must be matched, crimping mold specifications and core specifications consistent, crimping should be more than two.